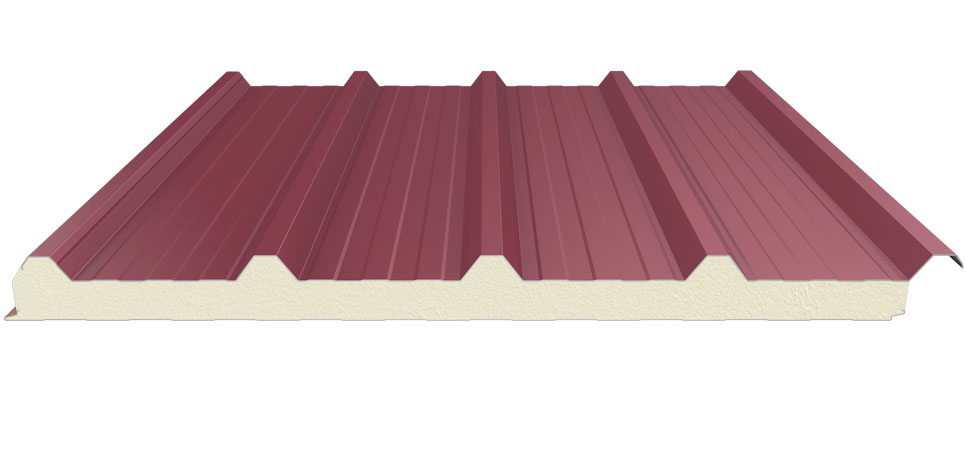

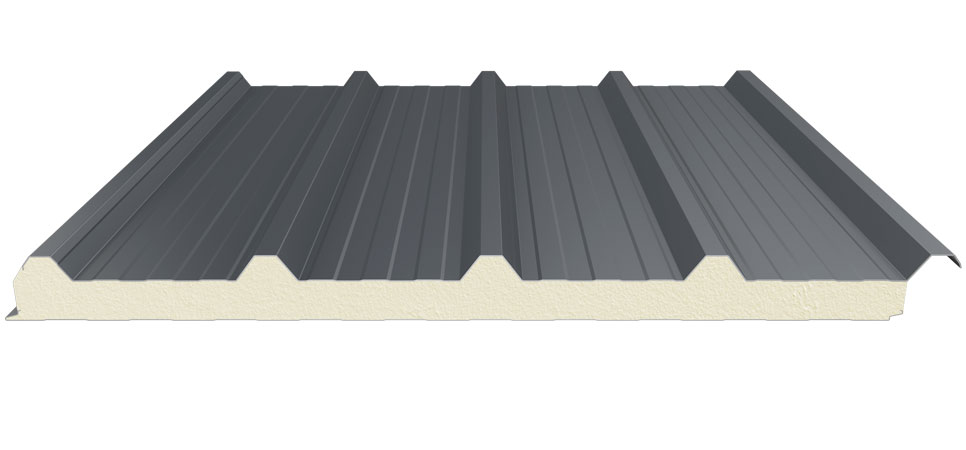

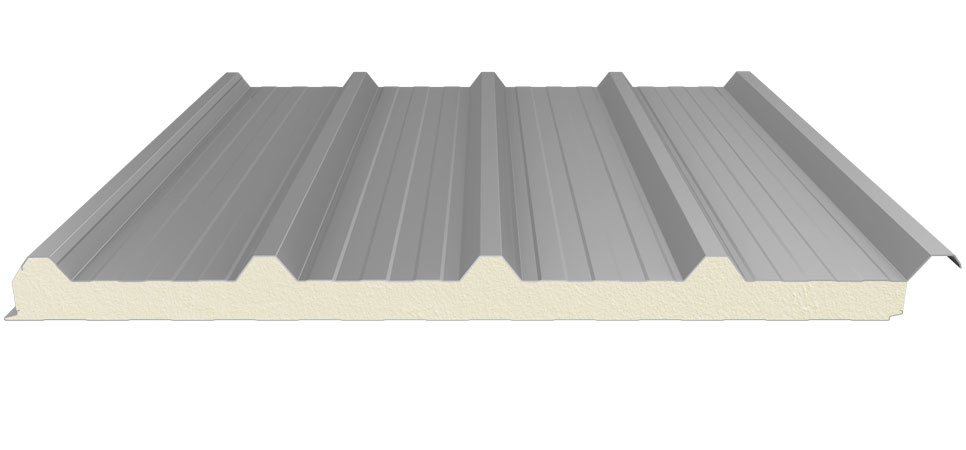

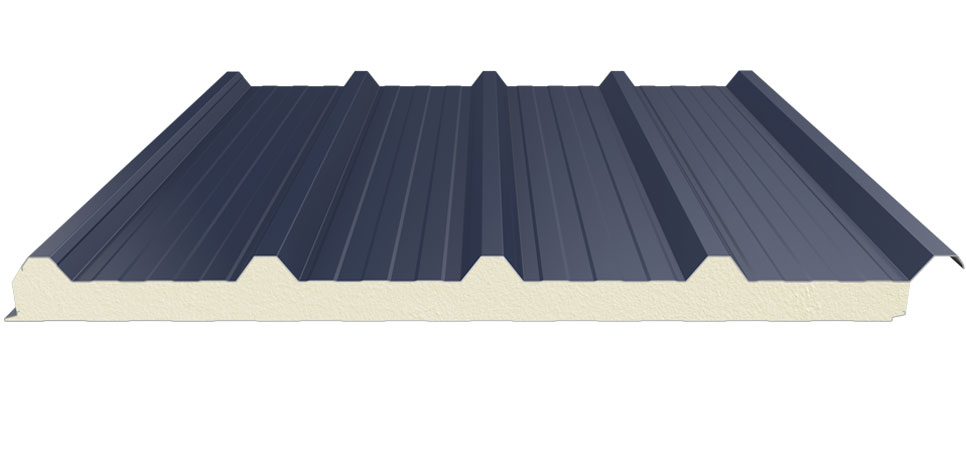

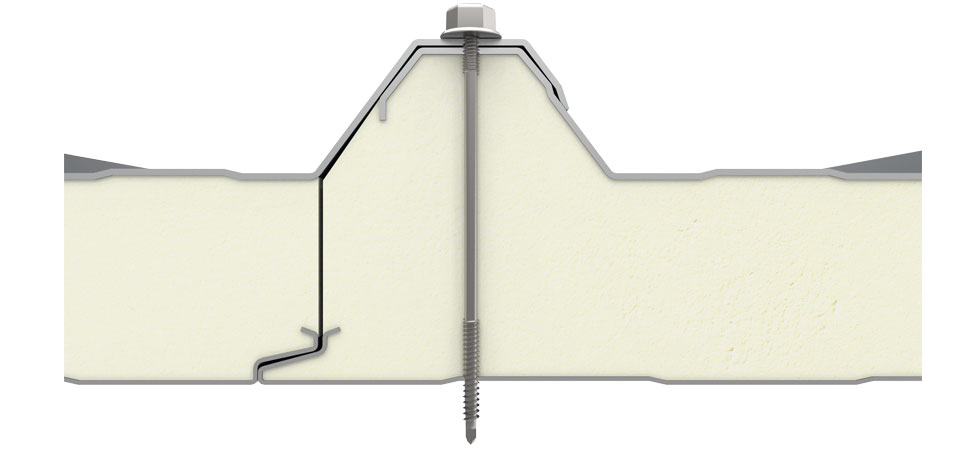

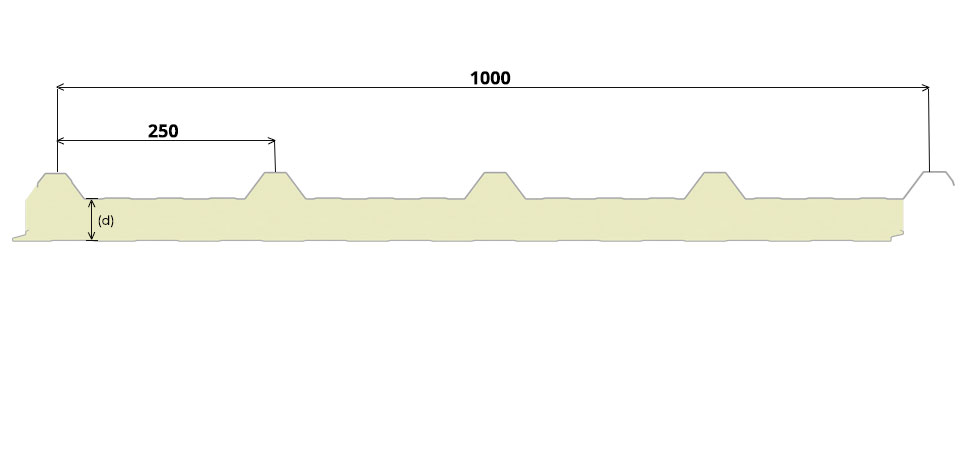

5 Ribs Roof Panel

Our 5-Rib Roof Panels eliminate the problem of water absorption with their polyurethane insulated features and stand out with their high carrying capacity. It offers solutions suitable for customer preferences by being produced in different forms, thus allowing you to get the most economical options. Additionally, it is resistant to high temperatures and does not spread flame in case of fire, providing a safe roof solution.

| Place of Use | Facade |

| Useful Width | 1000 mm |

| Minimum Length | 2,4 m |

| Maximum Length | Depends on Shipping Conditions |

| Polyurethane Density (EN 1602) | 40 (±2) kg/m³ |

| Polyurethane Thickness | 30-40-50-60-80-100 mm |

| Fire Classification (EN1350) | B, s2, d0 |

| Metal Type | Painted Galvanized Steel Sheet or Aluminium Sheet |

| Standard External Metal Thickness | 0,50 mm |

| Standard Internal Metal Thickness | 0,40 mm |

| PGSS | PGSS | PURLING SPACING | |||||||||

| Top Metal Thickness (mm) | Bottom Metal Thickness (mm) |

PUR (mm) |

150 cm | 175 cm | 200 cm | 225 cm | 250 cm | 275 cm | 300 cm | 325 cm | 350 cm |

| 0,50 | 0,40 | 40 | 370 | 299 | 245 | 200 | 170 | 142 | 123 | 106 | 93 |

| 0,50 | 0,40 | 50 | 508 | 408 | 332 | 264 | 231 | 193 | 166 | 143 | 123 |

| 0,50 | 0,40 | 60 | 646 | 518 | 422 | 344 | 295 | 244 | 208 | 175 | 154 |

| 0,50 | 0,40 | 80 | 916 | 733 | 597 | 489 | 412 | 344 | 294 | 249 | 218 |

| ALUMINIUM | ALUMINIUM | PURLING SPACING | |||||||||

| Top Metal Thickness (mm) | Bottom Metal Thickness (mm) |

PUR (mm) |

150 cm | 175 cm | 200 cm | 225 cm | 250 cm | 275 cm | 300 cm | 325 cm | 350 cm |

| 0,50 | 0,40 | 40 | 296 | 223 | 175 | 139 | 113 | 95 | 77 | 66 | 57 |

| 0,50 | 0,40 | 50 | 388 | 260 | 226 | 179 | 148 | 121 | 101 | 84 | 72 |

| 0,50 | 0,40 | 60 | 478 | 314 | 274 | 217 | 181 | 144 | 120 | 102 | 85 |

| 0,50 | 0,40 | 80 | 670 | 444 | 387 | 307 | 250 | 205 | 162 | 140 | 119 |

EN

EN  TR

TR