Polycarbonate

Coating Material

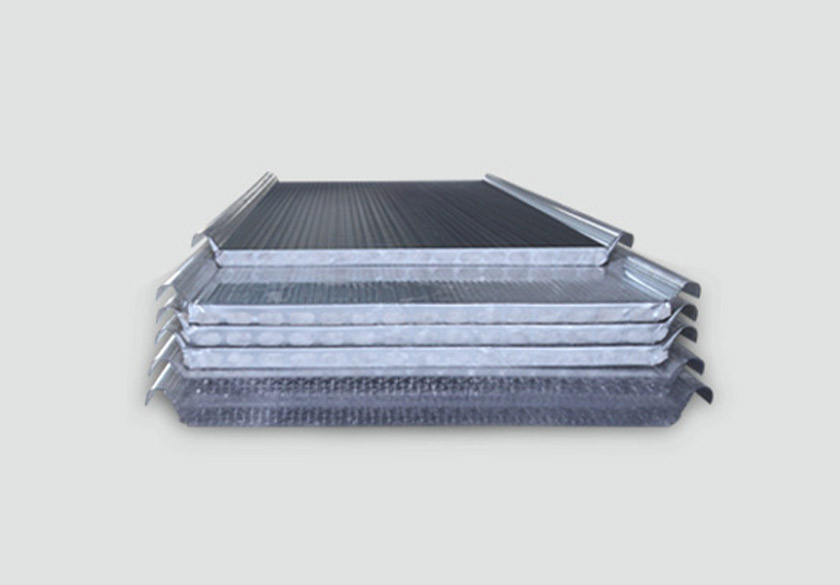

- It is made of polycarbonate and is transparent or white in color.

- The upper surface is coextruded and U.V. protected.

- It is approximately 80 mm cheek pitch height.

- The cheek turn is double-walled to provide high strength.

- It is designed for use between sandwich panels.

| Panel Width | 1000mm ± 15mm (left-right cheek center to center) |

| Panel Length | Desired size, custom size |

| Number of Walls / Structure | 7 Walls / X Structure |

| Panel unit weight | 3500gr/m2 (Tolerance ± 10%) |

| Heat Conduction Coefficient(K) | 1.10 W/m2K |

| Light Transmittance (LT %) | Transparent 50% (visible light transmittance) White 25% (visible light transmittance) |

| Usage Temperature | -40 ºC ~ + 120 ºC |

| Expansion/Contraction | 0.065 mm/m ºC |

| Combustion Resistance | EN 13501 EuroClass B-s1,d0 |

| Acoustic Insulation | 21dB |

| Coextruded U.V. | There is |

EN

EN  TR

TR