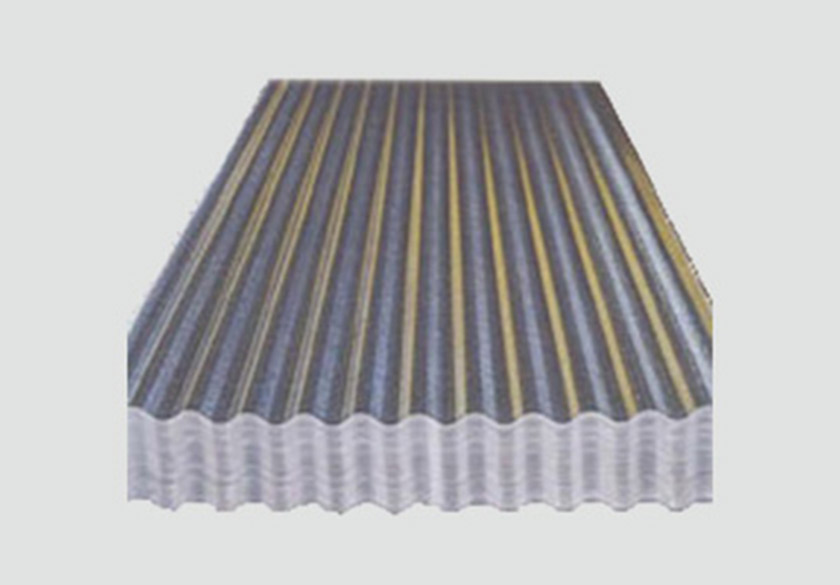

Galvanized Corrugated Sheet

Features:

- Corrosion Resistance

- Long Lasting

Usage Areas:

- Roof and Facade coatings

Technical Drawing:

DISTRIBUTED LOADS CAN BE CARRIED BY CORRUGATED PLATES (kg/m2)

| Galvanized Sheet Thickness (mm) | |||||||||||

| Purlin Range (m) | 0.30 | 0.35 | 0.40 | 0.45 | 0.50 | 0.60 | 0.70 | 0.80 | 0.90 | 1.00 | 1.20 |

| 1.00 | 208 | 243 | 278 | 312 | 347 | 451 | 520 | 590 | 659 | 693 | 833 |

| 1.10 | 172 | 200 | 230 | 258 | 287 | 373 | 430 | 487 | 545 | 574 | 688 |

| 1.20 | 144 | 169 | 193 | 217 | 241 | 313 | 361 | 410 | 458 | 482 | 578 |

| 1.40 | 106 | 124 | 142 | 159 | 177 | 230 | 266 | 301 | 336 | 354 | 425 |

| 1.50 | 92 | 108 | 123 | 139 | 154 | 200 | 231 | 262 | 293 | 308 | 370 |

| 1.80 | 64 | 75 | 86 | 96 | 107 | 139 | 161 | 182 | 203 | 214 | 257 |

| 2.00 | 53 | 61 | 69 | 78 | 87 | 113 | 130 | 148 | 165 | 173 | 208 |

| 2.20 | 43 | 50 | 57 | 65 | 72 | 93 | 108 | 122 | 136 | 143 | 172 |

| 2.40 | 36 | 42 | 48 | 54 | 60 | 78 | 90 | 102 | 114 | 120 | 145 |

| Sheet Thickness | Min. 0,30mm Max. 1,20mm |

| Sheet Length | Min. 1000mm Max.5000mm |

| Most Useful | 815mm (tolerance is +25mm, – 15mm) |

EN

EN  TR

TR