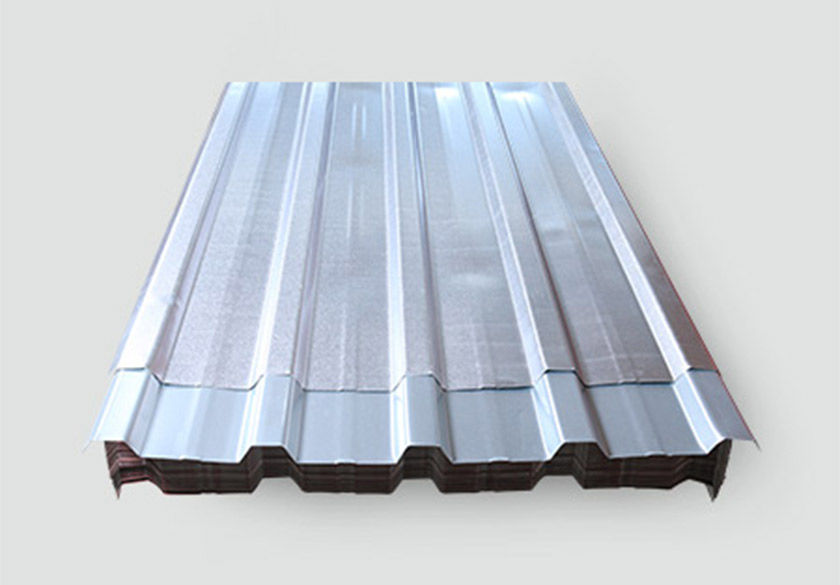

27/200 Galvanized Trapeze

Features:

- Corrosion Resistance

- Long Lasting

Usage Areas:

- Roof Facade Systems

Technical Drawing:

| Galvanized Sheet Thickness (mm) | |||||||

| Purlin Range (mm) | 0,50 | 0,60 | 0,70 | 0,80 | 0,90 | 1,00 | 1,20 |

| 1,20 | 411 | 536 | 617 | 701 | 782 | 824 | 989 |

| 1,40 | 302 | 393 | 453 | 515 | 575 | 605 | 726 |

| 1,50 | 264 | 343 | 396 | 449 | 501 | 528 | 634 |

| 1,80 | 183 | 238 | 275 | 312 | 348 | 367 | 440 |

| 2,00 | 149 | 193 | 223 | 252 | 282 | 297 | 356 |

| 2,20 | 123 | 160 | 184 | 209 | 233 | 245 | 295 |

| 2,40 | 103 | 134 | 155 | 175 | 196 | 206 | 248 |

| 2,80 | 95 | 98 | 114 | 129 | 144 | 152 | 182 |

| 3,00 | 66 | 86 | 99 | 112 | 125 | 132 | 158 |

| Moment of Inertia (j:cm4/m) | 6,71 | 8,73 | 10,07 | 11,41 | 12,75 | 13,43 | 16,11 |

| Moment of Strength (W:cm3/m) | 3,48 | 5,03 | 5,80 | 6,58 | 7,35 | 7,74 | 9,29 |

Safety Stress = 1200 kg/cm2. Calculations are based on continuous beam shape.

| Thickness | Min. 0,30mm - Max. 1,20mm |

| Size | Min. 0,40m - Max. 14m |

| Net Coating | 800mm ve 1000mm |

EN

EN  TR

TR