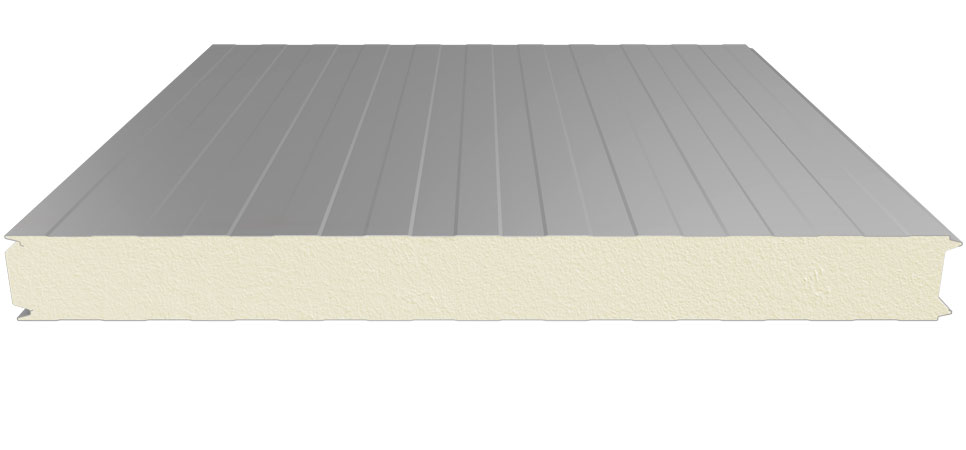

Cold Storage Room Panel

Cold Room Panels offer affordable and hygienic solutions for various facilities, from warehouses where frozen food products are stored to facilities where seafood is processed, from industrial cold storages to laboratories, from hospitals to meat and meat processing facilities, ice cream and fruit and vegetable warehouses.

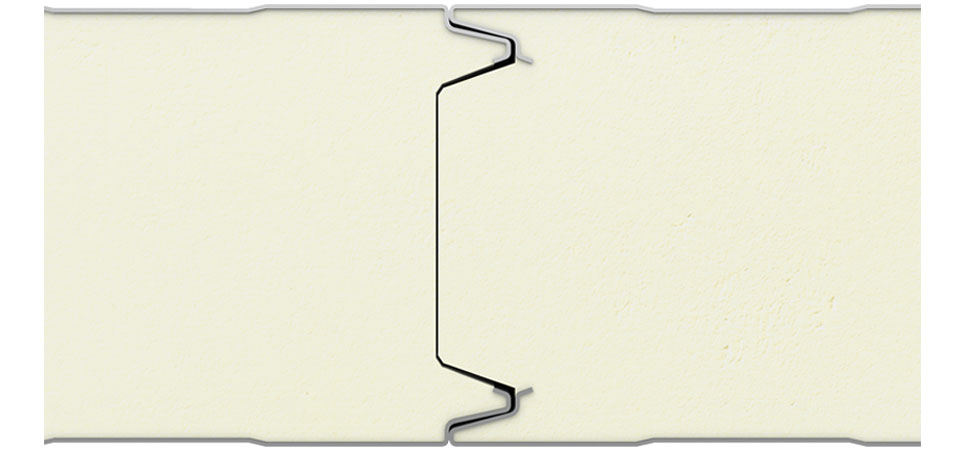

900CS and 1100CS products provide full protection against bacteria thanks to the special paints used on their surfaces, which allows them to be used safely as hygienic materials in cold rooms. The double-sided tongue and groove section creates a strong connection, providing a great advantage in insulation. These panel systems can be used on the ceiling coverings as well as the walls of cold storages.

|

Place of Use |

Facade |

|

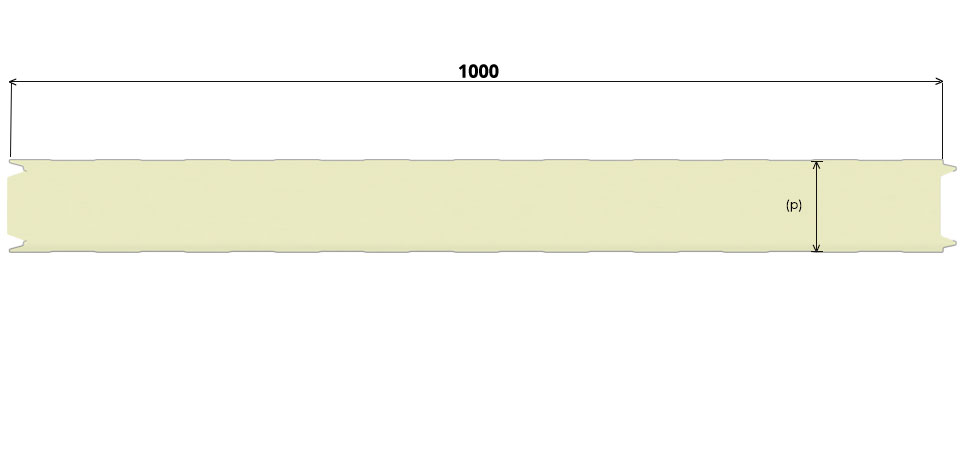

Useful Width |

1000-1050-1130 mm |

|

Minimum Length |

2,4 m |

|

Maximum Length |

Depends on Transportation Conditions |

|

Polyurethane Density (EN 1602) |

40 (±) kg/m3 |

|

Polyurethane Thickness |

50-60-80-100-120-150 mm |

|

Flammability Class (EN 13501) |

B, s2, d0 |

|

Metal Type |

Painted Galvanized Sheet |

| Standard External Metal Thickness |

0,50 mm |

| Standard External Metal Thickness |

0,40 mm |

|

Top Sheet Thickness (mm) |

Bottom Sheet Thickness (mm) |

PUR (mm) |

Max. Wall Height (m) |

Roof Opening (m) |

|

0,50 |

0,40 |

80 |

6,5 |

4 |

|

0,50 |

0,40 |

100 |

8 |

5 |

|

0,50 |

0,40 |

120 |

10 |

6 |

|

0,50 |

0,40 |

150 |

12 |

7 |

|

Temperature Difference between Inner and Outer Surface (°C) |

|||||||||||||||

|

PUR (mm) |

Panel UCS (W/m²K) |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

55 |

60 |

65 |

70 |

80 |

|

80 |

0,247 |

2,5 |

3,7 |

4,9 |

6,2 |

7,4 |

8,6 |

9,9 |

< 10 W/m2 |

||||||

|

100 |

0,199 |

2,0 |

3,0 |

4,0 |

5,0 |

6,0 |

7,0 |

8,0 |

9,0 |

< 10 W/m2 |

|||||

|

120 |

0,167 |

1,7 |

2,5 |

3,3 |

4,2 |

5,0 |

5,8 |

6,7 |

7,5 |

8,3 |

9,2 |

< 10 W/m2 |

|||

|

150 |

0,134 |

1,3 |

2,0 |

2,7 |

3,4 |

4,0 |

4,7 |

5,4 |

6,0 |

6,7 |

7,4 |

8,1 |

8,7 |

9,4 |

< 10 W/m2 |

EN

EN  TR

TR